Website by Marco A. Lopez-Sanchez - Last update: 2023-04-24

The IDEA project at a glance

The IDEA project stands for In-situ Deformation Experiments to study microstructure and texture evolution in Anisotropic crystalline materials. This is a research project attached to a Marie Skłodowska-Curie “Clarín”-COFUND Action postdoctoral fellowship starting in 2018 and funded by different sources including European and French research projects. The main goal of the project is to rationalize the physical processes that occur at the microscale during crystal-plastic deformation and heating. Specifically, we are interested in how recrystallization (dynamic and static) evolves and affect the properties of polycrystalline materials such as strain hardening/weakening, the crystal preferred orientation (CPO) and strain localization. Our approach involves tracking the evolution of microstructure, CPO, and strain field during recrystallization using in situ observations. We use two main techniques: electron backscatter diffraction (EBSD) and digital image correlation (DIC). The core team is based at Géosciences Montpellier (Université de Montpellier - CNRS) in France and consist of Andréa Tommasi (supervisor), Marco A. Lopez-Sanchez (the recipient of the Clarín-COFUND fellowship), and Fabrice Barou (Geosciences Montpellier). We also collaborate with David Mainprice (GM Montpellier), Maurine Montagnat (IGE - Grenoble) and Romain Quey (Mines Saint-Etienne).

1. Why the IDEA project?2. Equipment2.1 In situ deformation experiments using Electron Backscatter Diffraction2.2 Digital image correlation (ice experiments)What is digital image correlation and why using ice

1. Why the IDEA project?

Understanding how plate tectonics works remains a cornerstone of modern geology. Deformation on the lithosphere, the "rigid" outer layer of the Earth, mainly occurs in a localized fashion. Excepting for the first ~10 km where deformation occurs primarily through brittle faults, most of the lithosphere (~95 % in volume) deforms essentially through crystal-plastic processes. This mode of deformation typically involves the development of planar zones of intense deformation known as shear zones and dislocation creep processes. Understanding how strain localises and preserves at different depths is key to explain how plate boundaries and major faults form and evolve, and ultimately how plate tectonics works. Yet, fundamental rock behaviour (strength) and the causes of strain localization remain poorly understood.

Rationalize the mechanical response to forces at great depths (i.e. within the plastic field) is a challenge for several reasons:

Earth scientists do not have direct access (i.e. by drilling) to rocks deforming in the plastic field, usually involving rocks deeper than 10-15 km. Fortunately, orogenic processes bring these rocks to the earth's surface, many of which locally preserve the original microstructure and CPO.

Rock deformation experiments at high P and T are challenging to conduct and always occur at strain rates many orders of magnitude faster (<<10-7 s-1) than in nature (10-13-10-16 s-1). The latter also implies that we need to use higher stresses or temperatures than those operating at specific depths in the lithosphere. As a result, flow laws estimated in the laboratory have to be scaled up by many orders of magnitude with no guarantee that the parameters obtained are correct. It is therefore necessary to understand the basic principles of plastic deformation to validate them.

Rock behaviour during ductile deformation depends on many intrinsic (materials) and extrinsic (environmental) factors, including temperature, water fugacity, crystallographic preferred orientation, dislocation content, or grain size. In turn, these factors vary during the deformation and heating that shape the planet Earth and may show a strong degree of interdependence between them, making it difficult to separate their effects.

Here, we are particularly interested in the study of recrystallization (RX) processes, either during the application of differential stresses (dynamic RX) or under hydrostatic conditions (static RX), as both processes are very common in nature. Recrystallization processes affect three key parameters controlling rock strength: dislocation content, grain boundary area per unit volume (by locally decreasing or increasing the grain size), and CPO. The study of recrystallization is also a subject of intense research across different scientific disciplines due to its broad interest. For example, recrystallization processes are of great industrial importance in the processing of metallic alloys as they control the mechanical properties and behaviour of a material.

2. Equipment

2.1 In situ deformation experiments using Electron Backscatter Diffraction

We conduct extension deformation experiments with in-situ monitoring using the CamScan X500FE CrystalProbe EBSD-SEM at Géosciences Montpellier, an electron microscopy with an Electron Backscatter Diffraction (EBSD) system specifically designed to host such experiments (Fig. 1). The vacuum chamber of this SEM-EBSD is designed to hold different types of devices. In our case, an in-house ceramic stage for the heating experiments and a MT1000 tensile deformation stage provided by NewTec Scientific for the deformation experiments.

Fig. 1. At left the CamScan X500FE CrystalProbe, an SEM-EBSD system specifically designed for the measurement of crystal orientation while conducting in situ experiments. Note that the column of the microscope is tilted 70 degrees to keep the samples horizontal. Upper right, this is the in house ceramic stage (made by Fabrice Barou) used in the annealing experiments. The image was taken during a heating-cooling test with a sample of magnesium alloy AZ31, note the thermocouples attached to different parts of the device. Lower right, the MT1000 deformation stage with a sample in place.

Fig. 1. At left the CamScan X500FE CrystalProbe, an SEM-EBSD system specifically designed for the measurement of crystal orientation while conducting in situ experiments. Note that the column of the microscope is tilted 70 degrees to keep the samples horizontal. Upper right, this is the in house ceramic stage (made by Fabrice Barou) used in the annealing experiments. The image was taken during a heating-cooling test with a sample of magnesium alloy AZ31, note the thermocouples attached to different parts of the device. Lower right, the MT1000 deformation stage with a sample in place.

2.2 Digital image correlation (ice experiments)

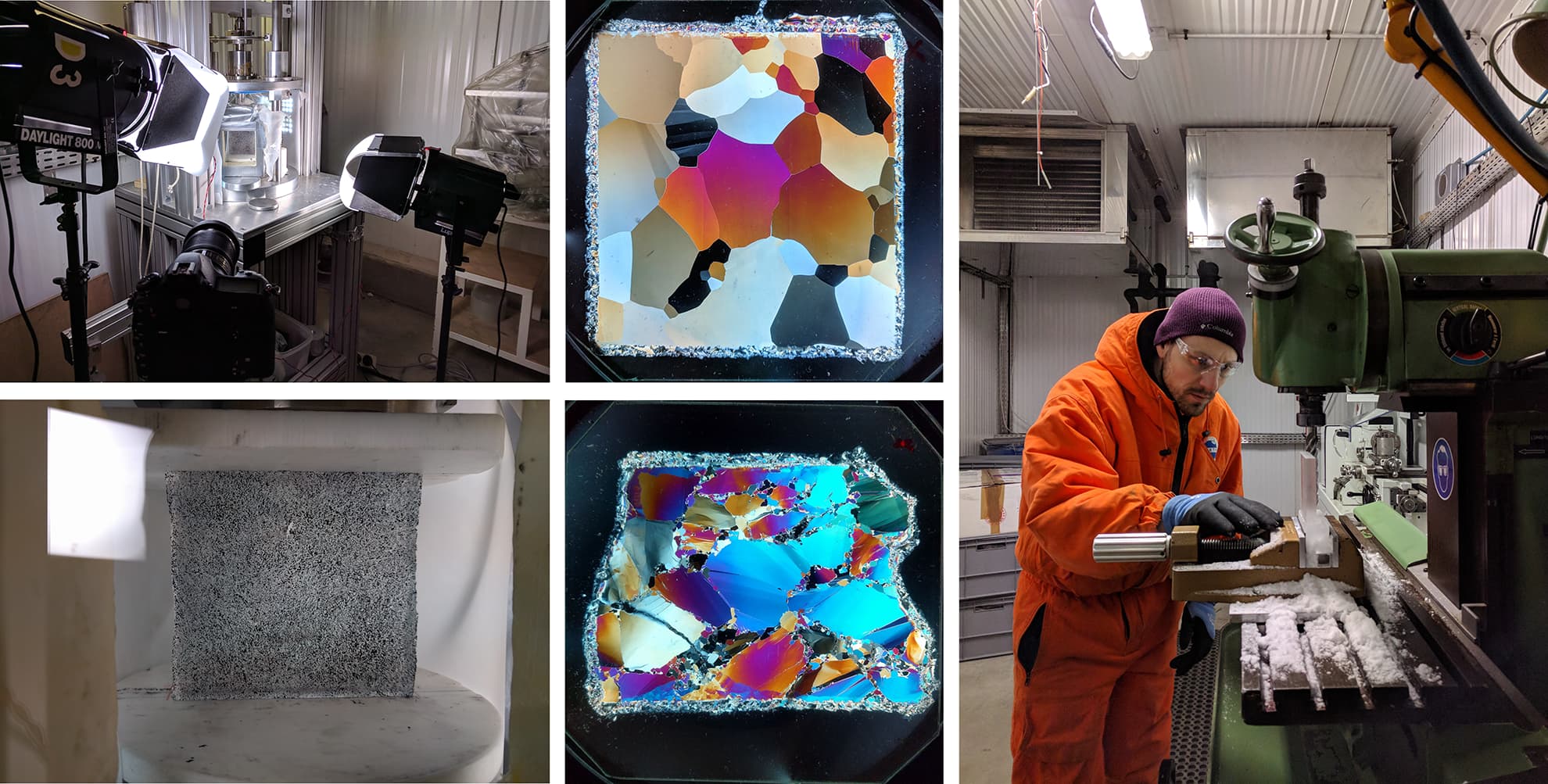

During the IDEA project, we carried out several creep experiments on ice using random patterns on its surface to track the evolution of plastic deformation using image correlation methods (Fig. 2). These experiments were carried out at the Institut des Géosciences de l’Environnement in Grenoble in collaboration with Dr. Maurine Montagnat. Samples (see details in the Materials section below) were deformed in unconfined compression using an in-house dead-weight rig at -7 ºC (0.97

Fig. 2. Left: set-up for the uniaxial compression creep ice test. Upper left, the full set-up with the creep rig in the background, and the camera equipment for the digital image correlation in the foreground. Lower left a close view of the ice sample within the creep rig. Note the random speckle on the surface of the sample to track displacements. Center: Thin sections using polarised light before (top) and after (bottom) the creep experiment (in this case a failed one). Note the recrystallisation at the grain boundaries and the heterogeneous plastic deformation. Right: That's me in the cold room making an ice sample with the milling machine.

Fig. 2. Left: set-up for the uniaxial compression creep ice test. Upper left, the full set-up with the creep rig in the background, and the camera equipment for the digital image correlation in the foreground. Lower left a close view of the ice sample within the creep rig. Note the random speckle on the surface of the sample to track displacements. Center: Thin sections using polarised light before (top) and after (bottom) the creep experiment (in this case a failed one). Note the recrystallisation at the grain boundaries and the heterogeneous plastic deformation. Right: That's me in the cold room making an ice sample with the milling machine.

What is digital image correlation and why using ice

Digital image correlation (DIC) is an image-based method that uses digital image recording and tracking techniques to make accurate 2D (or 3D) full-field measurements during the deformation of a sample. DIC of random speckle patterns has become one of the most accurate techniques nowadays for quantitative in situ displacement and strain full-field analysis at the grain and subgrain scales. However, the application of DIC methods at high homologous temperatures (> 0.9 Tm) and/or high plastic strains (>3%) remains challenging. The distribution of strain at high homologous temperatures cannot be yet measured in most materials due to their high melting temperatures, for example of dominant silicates forming the Earth lithosphere or most alloys in engineering. Typical problems at such temperatures include unstable speckle patterns and/or image distortions in optical devices caused by hot air turbulences due to heat radiation. Indeed, DIC methods have been mostly applied in metals at room temperatures. The application of the DIC technique in materials deforming at high homologous temperatures, where materials behave differently from deformation at moderate or low homologous temperatures, is thus a highly desirable goal. The low melting temperature (~0 ºC) of conventional (

Methods & equipment

Hardware: For the digital image acquisition, we used a Nikon D850 digital camera with a 45.7 Mp CMOS sensor (size of 35.9 x 23.9 mm with pixel area of 18.84 μm2) and a high-performance low-distortion Tamron SP Macro 1:1 lens (focal length of 180 mm, maximum aperture of f/3.5).

Image sequence: We took 30 images before starting the deformation experiment and then every 10 minutes during ice creep (see Figure 2 for general set-up). Creep experiments last between one and two days.

Digital image correlation (DIC): We used the free and open-source Digital Image Correlation Engine (DICe) from Sandia National Laboratories to compute the full-field displacements and strains from sequences of digital images. The data obtained by the DICe tool was treated and plotted using in-house Python codes released as free and open-source Jupyter Notebooks. See examples at https://github.com/marcoalopez/Jupyter4DICe

3. Materials

We use three different materials: magnesium alloy AZ31, ice, and olivine.

Magnesium

We use commercial-purity AZ31 magnesium alloy (~96% Mg, ~3% Al, ~1% Zn) for the in situ EBSD experiments as we need a material that easily undergoes dynamic recrystallization under low-P and moderate T conditions operating in an SEM-EBSD chamber. Despite being an alloy, magnesium aggregates have been used as rock analogue before since it shares several features with major rock-forming minerals due to its low crystal symmetry (hexagonal):

highly anisotropic properties

deform plastically by a few slip systems, mainly through the sliding of the basal plane (normal to the crystal c-axis)

prone to undergo dynamic recrystallization

Furthermore, magnesium alloys have attracted increasing attention in the last two decades due to their low mass density compared to other conventional metallic materials and good mechanical properties, making them candidates for the next generation of light-weight metallic materials. We have used two types of AZ31 alloy samples, small cubes of 10x10x8 mm for the annealing experiments (Fig. 3), and dog-bone specimens for the tensile tests.

Fig. 3. AZ31 magnesium alloy samples used in the IDEA project. Upper left, AZ31 specimens of 10x10x8 mm before and after deformation in a channel-die compression device (i.e. plane strain) used for the annealing experiments. Upper right, dog-bone specimens used for the tensile tests. Lower, crystal preferred orientation (left) and microstructure (right) of the as-received magnesium alloy used for the annealing experiments. Note the intense basal texture with the c-axis maximum above eight multiples of a uniform distribution. The apparent mean grain size is ~9 μm (mode ~5 μm), and most grains had an internal misorientation spread lower than 1%.

Fig. 3. AZ31 magnesium alloy samples used in the IDEA project. Upper left, AZ31 specimens of 10x10x8 mm before and after deformation in a channel-die compression device (i.e. plane strain) used for the annealing experiments. Upper right, dog-bone specimens used for the tensile tests. Lower, crystal preferred orientation (left) and microstructure (right) of the as-received magnesium alloy used for the annealing experiments. Note the intense basal texture with the c-axis maximum above eight multiples of a uniform distribution. The apparent mean grain size is ~9 μm (mode ~5 μm), and most grains had an internal misorientation spread lower than 1%.

Ice

Ice

Our main goal with these creep experiments is to understand how strain localise and/or delocalised at grain scale, how this phenomenon is affected by local grain interactions, and which are the links between the strain field and the development of intracrystalline distortion and dynamic recrystallization. These issues have implications for the modelling of the deformed state of polycrystalline materials at the microstructural scale using continuum mechanics.

See a lecture on this issue here: https://youtu.be/R5Vm63oqLGk

Olivine

Olivine is the main mineral phase in the lithospheric Earth’s mantle and thus a key mineral to understand lithosphere deformation. In the IDEA project, we perform no olivine deformation experiments but we used all the EBSD data-treatment procedures developed within the frame of the project to reanalyse and reinterpret old datasets coming from unpublished olivine extension deformation experiments. More specifically, we used a dataset that comes from olivine-rich cylinders cored from natural peridotites deformed in extension in a gas-medium apparatus at a confining pressure of 300 MPa and T of 1200ºC (Fig. 4). Our main goal is to understand how a common type of dynamic recrystallization, called sub-grain rotation, develops in olivine and what effects it has on the CPO and the rheology of peridotites.

See a lecture on this issue here: https://youtu.be/vs6-znNYAMM

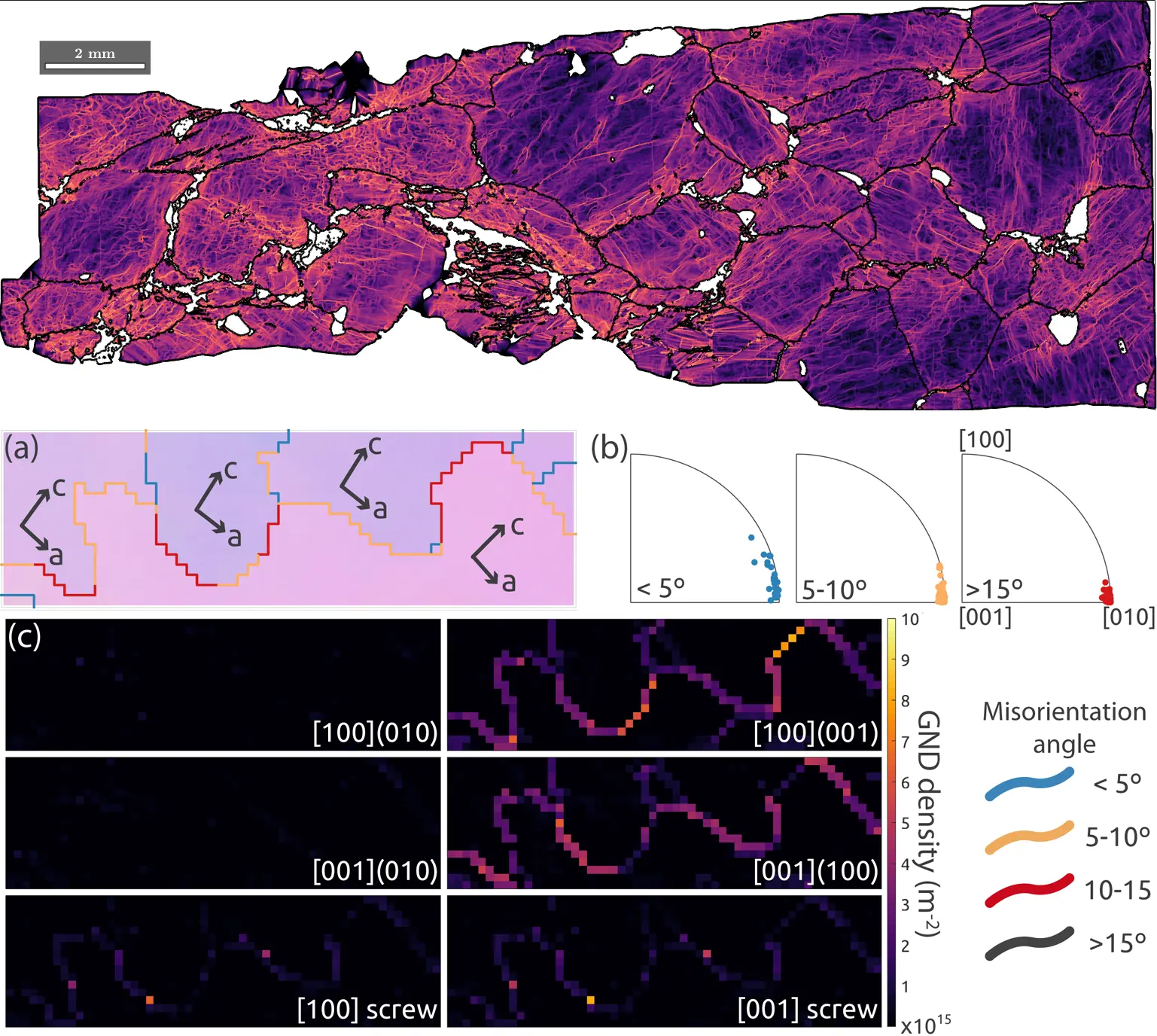

Fig. 4. At the top, kernel average misorientation (KAM) map using EBSD of half of one of the deformed peridotite cylinders, note the necking effect towards the left due to the extension. KAM is an indicator of crystal lattice distortion due to the presence of dislocations, yellow colours indicate higher lattice distortions. Note how the zones with high KAM values define tangles of subgrains and how these are much more developed towards the neck area. At the bottom, detail of a zig-zag subgrain showing data on the misorientation it accommodates (angle and axis) and the types of dislocation of which they are formed. For more info see here https://doi.org/10.1016/j.tecto.2021.228916

Fig. 4. At the top, kernel average misorientation (KAM) map using EBSD of half of one of the deformed peridotite cylinders, note the necking effect towards the left due to the extension. KAM is an indicator of crystal lattice distortion due to the presence of dislocations, yellow colours indicate higher lattice distortions. Note how the zones with high KAM values define tangles of subgrains and how these are much more developed towards the neck area. At the bottom, detail of a zig-zag subgrain showing data on the misorientation it accommodates (angle and axis) and the types of dislocation of which they are formed. For more info see here https://doi.org/10.1016/j.tecto.2021.228916

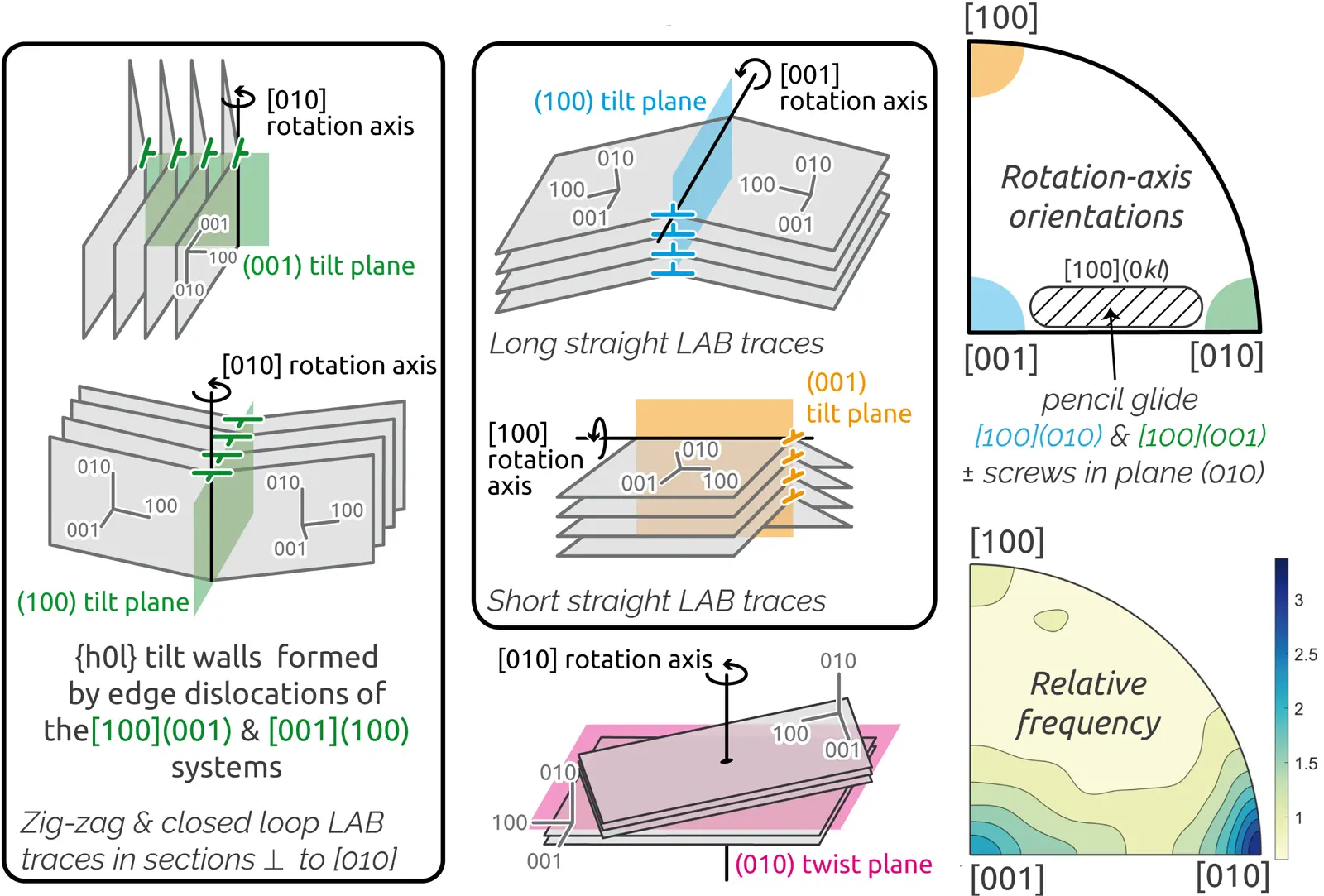

Fig. 5. Families of dislocation types that make up the different subgrains in olivine, which are the precursors of the grain boundaries that will form the new recrystallised grains, in the studied samples. For more info see here https://doi.org/10.1016/j.tecto.2021.228916

4. Publications

Lopez-Sanchez MA, Chauve T, Montagnat M, Tommasi A. (2023) Decoupling between strain localisation and the microstructural record revealed by in-situ strain measurements in polycrystalline ice. Earth and Planetary Science Letters 611: 118149. https://doi.org/10.1016/j.epsl.2023.118149

Supplementary material: https://www.sciencedirect.com/science/article/pii/S0012821X23001620?via%3Dihub#se0160

Relevance: We explore the links between strain localisation and microstructure evolution in polycrystal ice samples deformed in the dislocation creep regime using digital image correlation (DIC) techniques. By comparing the evolution of the strain field and the microstructure we prove that grains can accommodate large strains with little or no local accumulation of dislocations depending on the active slip system, i.e. the grain changes its shape without generating large intracrystalline distortions. This observation, extensible to other plastically anisotropic minerals such as quartz or olivine, implies that (1) intracrystalline distortion is not a reliable indicator of the accumulated strain at grain scale or smaller and that (2) the proportion of different dislocation types in the subgrains does not gauge their relative contribution to deformation. The latter allowed us to solve why the high presence of non-basal dislocations in ice subgrains, hitherto considered paradoxical, since our data indicate that this paradox is apparent. PDF here

Lopez-Sanchez MA, Tommasi A, Barou F, and Quey R (2020) Dislocation-driven recrystallization in AZ31B magnesium alloy imaged by quasi-in situ EBSD in annealing experiments. Materials Characterization 165:110382 https://doi.org/10.1016/j.matchar.2020.110382

Relevance: When heating a polycrystalline material (annealing) new grains nucleate and grow in a process called static recrystallization. This changes the microstructure and texture of the aggregate modifying its properties (mechanical and seismic). Annealing is a common process in the Earth's lithosphere and industry and, thus, of wide interest. Despite this, it is not clear which factors other than temperature control the growth process the most, the usual suspects being the disappearance of grain boundary surfaces with unfavourable (high-energy) configurations or the energy stored in the form of dislocations (a crystallographic defect within a crystal structure induced during deformation) in the aggregate. To study this, we deformed several magnesium alloy specimens under different conditions to generate different microstructures and textures. Then, we led a series of in situ EBSD heating experiments at the same temperature to demonstrate that the local accumulation of dislocations is an important factor controlling the growth of new grains in highly deformed polycrystalline materials. We established new microstructural proxies based on EBSD data to demonstrate this effect. PDF here

Lopez-Sanchez MA, Tommasi A, Ben Ismail W, Barou F. (2021) Dynamic recrystallization by subgrain rotation in olivine revealed by electron backscatter diffraction. Tectonophysics, in press: 228916 https://doi.org/10.1016/j.tecto.2021.228916

Supplementary material (Matlab codes): https://doi.org/10.6084/m9.figshare.16569396.v1 (for full datasets see section 4.2)

Relevance: We study a widespread (in the lithosphere) dynamic recrystallization process called subgrain rotation in olivine, the most common mineral in the lithosphere. Using high-resolution EBSD, we were able to describe how and where the so-called “subgrain cells” (the precursor of the new recrystallized grains) form at micrometric scales and found a sharp change in the properties of these "subgrain boundaries" once they become grain boundaries. We discuss the possible causes of this change and propose a hypothesis to explain it. PDF here

Ben Ismail W, Tommasi A, Lopez-Sanchez MA, Barou F, Rutter EH, Demouchy S. Deformation of upper mantle rocks with contrasting initial fabrics in axial extension. Tectonophysics 815: 228916 https://doi.org/10.1016/j.tecto.2021.228916 Preprint here

Relevance: We deformed a set of natural upper mantle rocks in a HT-HP deformation device up to 50% in axial extension. We show that grain size variations representative of those observed in natural peridotites can lead to significantly different microstructure evolutions and mechanical behaviours (softening vs. hardening) and propose a hypothesis as to why this occurs.

Lopez-Sanchez MA (2020) Which average, how many grains, and how to estimate robust confidence intervals in unimodal grain size populations. Journal of Structural Geology 135:104042 https://doi.org/10.1016/j.jsg.2020.104042

Relevance: The average grain size and the grain size populations are some of the most used features to study the microstructure of rocks and in particular recrystallization. This paper provides guidelines for determining average grain sizes and confidence intervals from grain size populations. Using computer simulations and resampling techniques, we found that the geometric mean and the confidence intervals for the geometric mean provide the best balance between efficiency and robustness (being the median the best alternative) in recrystallized grain size populations. PDF here

Lopez-Sanchez MA, Chauve T, Montagnat M, Tommasi A. Strain localisation and microstructure evolution in polycrystalline ice by in-situ strain field measurements. Pre-print at EarthArXiv In review in Earth and Planetary Science Letters.

4.1 Codes released

Jupyter4DICe: A series of Jupyter notebooks written in Python for post-processing digital image correlation (DIC) data obtained with the free open-source digital image correlation tool DICe (under development!)

4.2 Datasets & multimedia content

Datasets

EBSD datasets used in Lopez-Sanchez et al. (2020) Materials Characterization 165:110382 http://dx.doi.org/10.17632/ttvh2m9r9s.1

EBSD datasets used in Lopez-Sanchez et al. (2021) Tectonophysics in press: 228916 http://dx.doi.org/10.17632/8dm87k7cm8.1

Multimedia

Videos of the experiments available soon

Links to talks

Dynamic recrystallization by subgrain rotation in olivine revealed by EBSD. Youtube video based on the talks given by Marco A. Lopez-Sanchez in the MTEX workshop 2022 and the EBSD2022 Topical Conference of the Microanalysis Society.

Evolution of strain field and microstructure in polycrystalline ice using in situ experiments. Youtube video based on the talks given by Marco A. Lopez-Sanchez years at various international meetings and workshops; e.g. 6th International Workshop on Rock Physics, GDR workshop 2021, RhEoVOLUTION workshop 2022.

In-situ annealing EBSD experiments in magnesium alloy AZ31B with variable deformation microstructures at Ecole de Physique des Houches (GRD Recrystallization and Grain Growth meeting 2020)

Dynamic recrystallization by sub-grain rotation in olivine-rich rocks at Ecole de Physique des Houches (GRD Recrystallization and Grain Growth meeting 2020)

5. Outreach and workshops

Workshop “EBSD data treatment with MTEX” at GRD Recrystallization and Grain Growth workshop 2020 at Les Houches, School of Physics, France

Copyright © 2018-2023 Marco A. Lopez-Sanchez

Information presented on this website is provided without any express or implied warranty and may include technical inaccuracies or typing errors; the author reserve the right to modify or enhance the content of this website at any time without previous notice. This webpage is not liable for the content of external links.

Hosted on GitHub Pages — Website created with Typora